An explanation of flushing

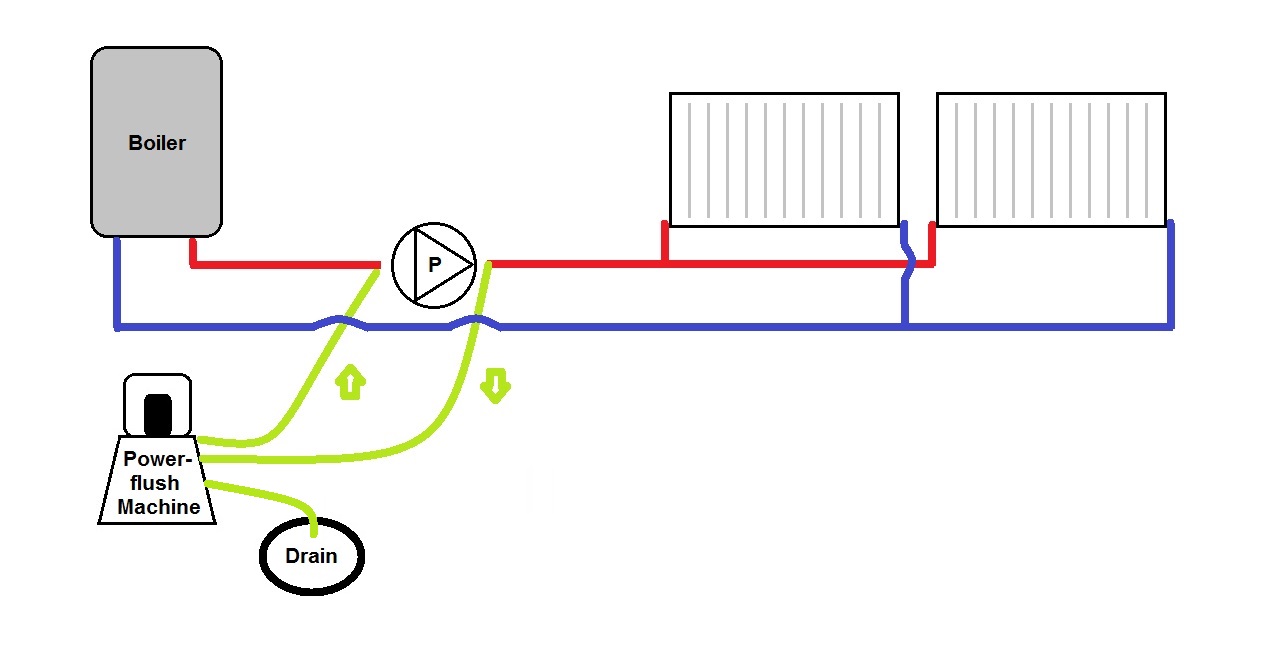

Powerflushing using a powerflush machine

A Powerflush machine is essentially a bucket of water with a high pressure pump on top.

Powerflushing using a powerflush machine is the best way to clean out systems where is is difficult to run fresh water through a system under mains pressure, such as a conventional low pressure tank fed system where you would have a small feed and expansion tank in your loft.

1. The F&E tank is isolated from the system and the pump or boiler is removed or isolated.

2. The powerflush machine is connected to allow water to flow through the radiators and back to the machine.

3. A cleaning chemical is added and the water is circulated aroung the system for at least an hour.

4. A hosepipe from a cold tap is run to the powerflush machine, a drain hose is connected from the powerflush machine to a suitable drain.

5. The tap is turned on and the drain hose isolator is opened, all radiators but one are turned off.

6. The water runs through the one open radiator, the radiator has been agitated to dislodge any debris

7. Once the water at the drain is clear the next radiator is opened and the last one shut, back to step 6.

8. Once all the radiators are cleaned the flush is complete, the valves are all re-opened, boiler, pump & F&E Tank re-instated, inhibior added.

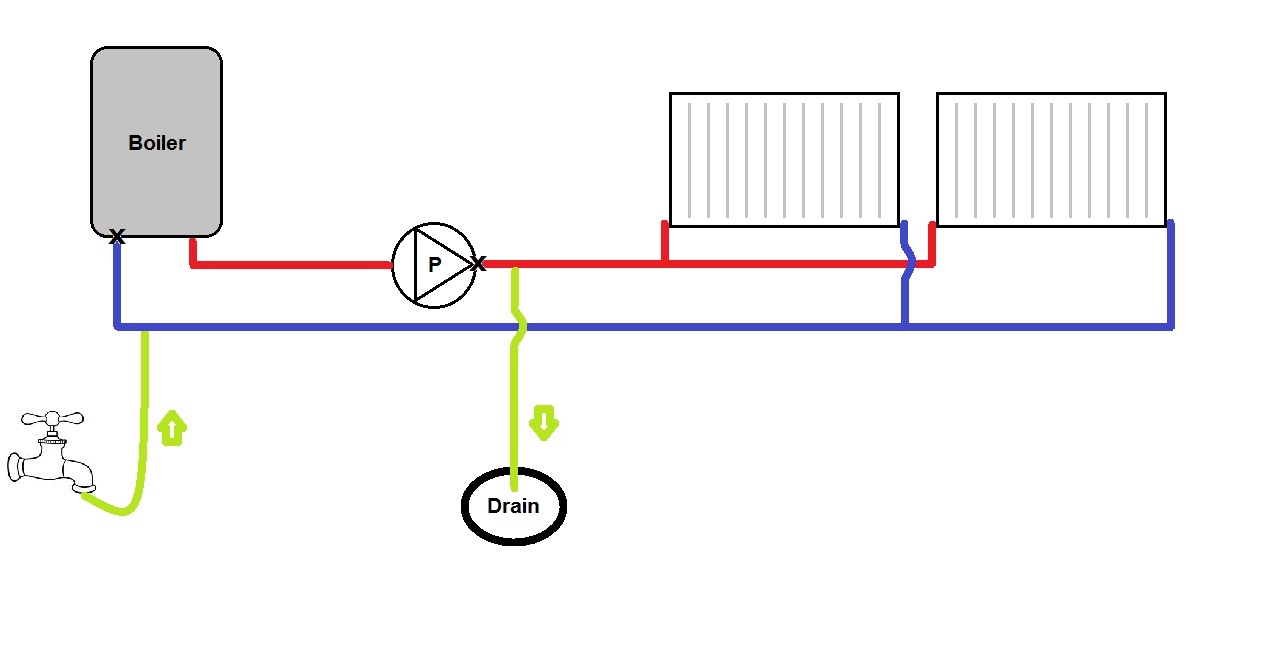

Powerflushing using mains pressure

Powerflushing using mains pressure is the best way to clean out systems that are connected via a filling loop to the incoming cold water mains, such as a combi boiler or a conventional high pressure sealed system where you would have an expansion vessel (usually red) instead of a feed and expansion tank.

1. The boiler is isolated to prevent water running through the boiler not the radiators.

2. A drain hose is connected onto the opposite pipe to which the filling loop is attached.

3. The filling loop isolators are turned on and the drain hose isolator is opened, all radiators but one are turned off.

4. The water runs through the one open radiator, the radiator has been agitated to dislodge any debris

5. Once the water at the drain is clear the next radiator is opened and the last one shut, back to step 4.

6. Once all the radiators are cleaned the cold mains flush is complete, if required the system can then be hot flushed by re-opening the boiler isolation, closing the drain off and running the system for an hour to lift and additional sludge/debris, (the system filter on the boiler return will protect the boiler during this time). The hot flush is a repeat of steps 1-5.

Common myths and misconceptions

A domestic circulator - This is often known as the pump, even heating engineers often refer to this circulator as a 'pump', it is usually found in the airing cupboard on the flow pipework or inside a combi boiler. A circulator circulates water using an impeller it does not pump water and put it under pressure.

Magnetic Cleanse or MagnaCleanse - This involves using the domestic circulator to circulate water around the system past a powerfull magnet that picks up iron oxide & iron/steel particles in the water, it does not remove any other debris or acidic water in the system.

Powercleanse - a powercleanse is where the system is flushed out without touching the radiator valves, the water will take the easiest route and very little debris will actually be removed from the system.